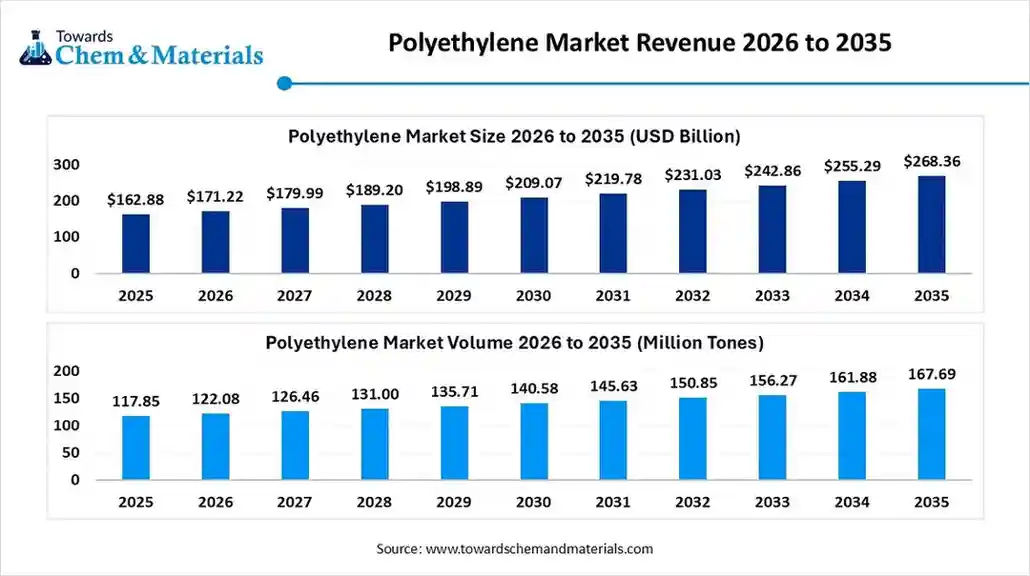

Polyethylene Market Volume to Worth 167.69 Million Tons by 2035

According to Towards Chemical and Materials, the global polyethylene market volume was valued at 122.08 million tons in 2026 and is expected to be worth around 167.69 million tons by 2035, exhibiting at a compound annual growth rate (CAGR) of 7.10% over the forecast period from 2026 to 2035. The market is driven by packaging industry demand, sustainability practices, technological innovations, and regulatory pressure

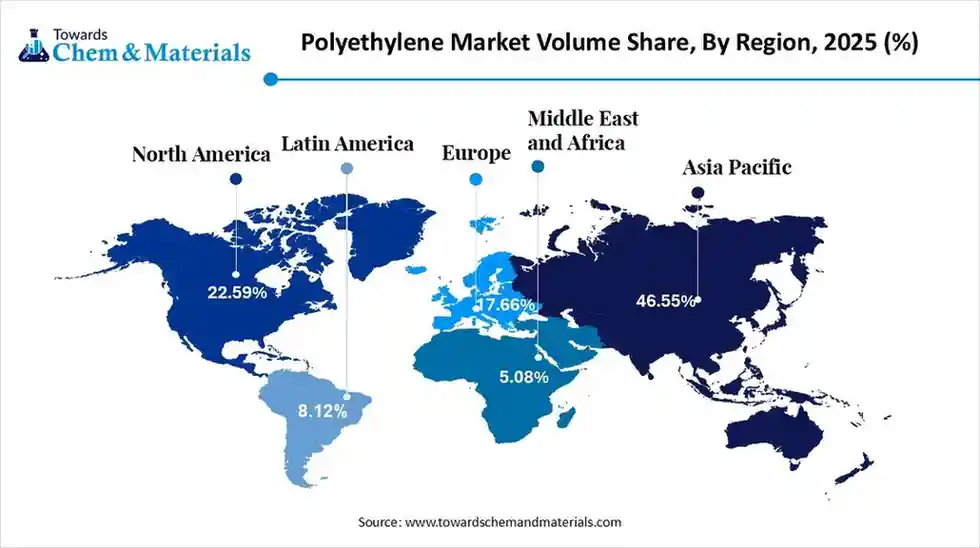

Ottawa, Jan. 12, 2026 (GLOBE NEWSWIRE) -- The global Polyethylene market size was estimated at USD 162.88 billion in 2025 and is expected to increase from USD 171.22 billion in 2026 to USD 268.36 billion by 2035, growing at a CAGR of 5.12%. In terms of volume, the market is projected to grow from 117.85 million tons in 2025 to 167.69 million tons by 2035. exhibiting at a compound annual growth rate (CAGR) of 7.10% over the forecast period 2026 to 2035. The Asia Pacific dominated Polyethylene market with the largest volume share of 51.52% in 2025. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5545

Polyethylene Market Report Highlights

- The Asia Pacific dominated the global polyethylene market with the largest volume share of 43% in 2025.

- The polyethylene market in North America is expected to grow at a substantial CAGR of 3.84% from 2026 to 2035.

- The Europe polyethylene market segment accounted for the major volume share of 17.66% in 2025.

- By product type, the High-density Polyethylene (HDPE) segment dominated the market and accounted for the largest volume share of 52.2% in 2025.

- By product type, the Low-density Polyethylene (LDPE)segment is expected to grow at the fastest CAGR of 3.56% from 2026 to 2035 in terms of volume.

- By Application, the Bottles & Containers segment led the market with the largest revenue volume share of 42.11% in 2025.

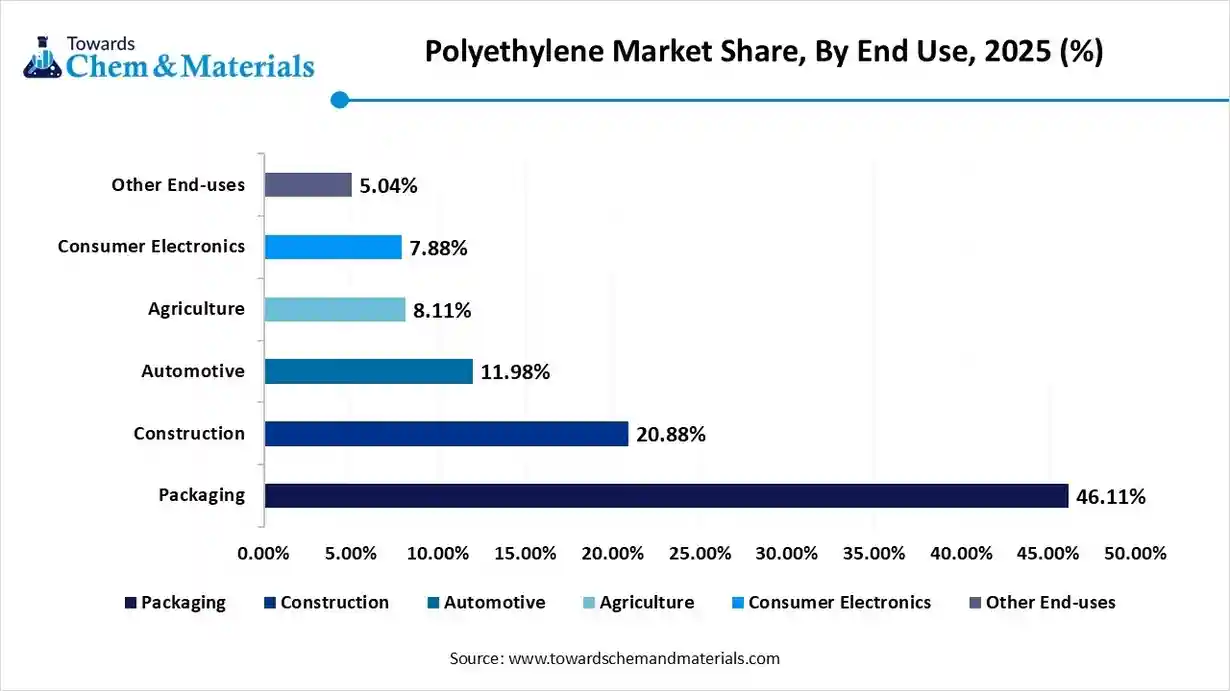

- By end use, the packaging segment dominated the market and accounted for the largest volume share of 47.64% in 2025.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

What is Going on in the Polyethylene Industry?

The polyethylene market is experiencing rapid growth driven by rapid urbanization and industrialization, the fast-growing population density, and the expansion facilitates the development of robust demand for consumption infrastructure in packaged food, construction materials like PE pipes, and insulation. The global shift towards circular economy principles is reshaping the investment and adoption of mechanical and chemical recycling technologies. This trend focuses on innovation in material recovery.

What Are the Major Trends in the Polyethylene Market?

- End-Use Applications: The flexibility of polyethylene boosts applications in Different Sectors. It includes pipes in Construction, lightweight components in automotive, and the packaging sector, which not only broadens the market but also drives the growth of the e-commerce sector, in this way promoting Stability and improving efficiency.

- Strict Environmental Regulations: The key driver that shapes this trend is driven by enforcing stricter laws regarding plastic waste, and regulatory pressure pushes manufacturers to innovate eco-friendly alternatives.

Uses of Poly(ethene) (Polyethylene)

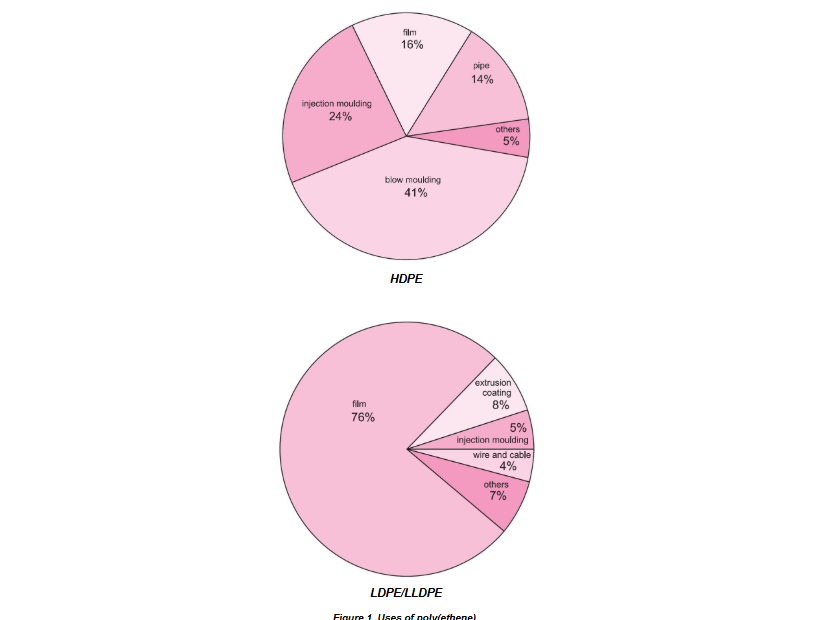

Poly(ethene), commonly known as polyethylene, is produced in three main forms based on density:

- Low-density polyethylene (LDPE) – density below 0.930 g/cm³

- Linear low-density polyethylene (LLDPE) – density around 0.915–0.940 g/cm³

-

High-density polyethylene (HDPE) – density around 0.940–0.965 g/cm³

LDPE and LLDPE are mainly used where flexibility is required. These materials are widely preferred for film packaging, such as plastic bags and wraps, as well as for electrical insulation due to their excellent insulating properties.

HDPE, on the other hand, is stronger and more rigid. It is commonly blow-moulded to manufacture containers used for household chemicals, including detergent and washing-up liquid bottles, as well as large drums for industrial packaging. HDPE is also extensively extruded into pipes, where strength and durability are essential.

All forms can be used for injection-moulded products such as buckets, food boxes and washing-up bowls (Table 1).

| Process | HDPE | LDPE | LLDPE |

| Making film | Food packaging Shopping bags |

Cling film Milk carton lining |

Stretch film |

| Injection moulding | Dustbins Crates |

Buckets Bowls |

Food boxes |

| Blow moulding | Detergent bottles Drums |

Squeezable bottles | |

| Extrusion | Water pipes | Flexible water pipes Cable jacketing |

Cable coating |

What everyday products are made from polyethylene?

Polyethylene (PE) is a versatile plastic used to make many everyday products. High-density polyethylene (HDPE) is used to make bottles for milk and household cleaners, grocery bags, toys, and appliance housings. Low-density polyethylene (LDPE) is used in packaging film, trash bags, squeeze bottles, and wire and cable insulation. Polyethylene can also be modified into synthetic fibers or to have elastic, rubber-like properties.

How is polyethylene made in factories?

In factories, polyethylene is created through the polymerization of ethylene (C2H4), a gaseous hydrocarbon derived from natural gas or petroleum cracking. This process involves breaking the double bond between carbon atoms in ethylene molecules (CH2=CH2) using polymerization catalysts. This creates extra single bonds that link to other ethylene molecules, forming long, chainlike molecules with repeating units.

The reaction conditions, including pressure, temperature, and catalyst type, determine the properties of the polyethylene produced. For example, low-density polyethylene (LDPE) is made under high pressure and temperature with peroxide initiators, resulting in a branched structure. High-density polyethylene (HDPE) is produced at lower temperatures and pressures using Ziegler-Natta catalysts or activated chromium oxide, resulting in a linear structure.

What are the main types of polyethylene?

Polyethylene (PE) is a light, versatile synthetic resin made by polymerizing ethylene. The main types of polyethylene include:

- Low-density polyethylene (LDPE) LDPE is very flexible because its branches prevent molecules from packing closely. It is used in packaging film, trash and grocery bags, and toys.

- Linear low-density polyethylene (LLDPE) LLDPE is structurally similar to LDPE but is made by copolymerizing ethylene with other compounds using Ziegler-Natta or metallocene catalysts.

- High-density polyethylene (HDPE) HDPE is a strong, stiff, and highly crystalline material. It is used to make bottles, pails, and appliance housings.

- Ultrahigh molecular weight polyethylene (UHMWPE) With molecular weights of 3 to 6 million atomic units, UHMWPE can be spun into fibers with high stiffness and tensile strength. These fibers can be woven into bulletproof vests.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5545

Polyethylene Market Report Scope

| Report Attribute | Details |

| Market Size / Volume in 2026 | USD 171.22 Billion/ 122.08 Million Tones |

| Expected Size/ Volume in 2035 | USD 268.36 Billion/ 167.69 Million Tons |

| Growth rate | CAGR of 5.12% from 2024 to 2030 |

| Historical data | 2019 - 2025 |

| Forecast period | 2026 - 2035 |

| Quantitative units | Volume in kilotons, revenue in USD million, and CAGR from 2026 to 2035 |

| Report coverage | Volume forecast, revenue forecast, competitive landscape, growth factors, and trends |

| Segments covered | By Product Type, By End Use, By Application, By region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; China; India; Japan; South Korea; Australia, Brazil; Argentina; Saudi Arabia ; UAE ; South Africa |

| Key companies profiled | BASF SE; Borealis AG, Braskem; Dow; Exxon Mobil Corp.; Formosa Plastics; INEOS Group; LG Chem; LyondellBasell Industries Holdings B.V.; Mitsubishi Chemical Corp.; MOL Group; SABIC; China Petrochemical Corp. (Sinopec) |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Polyethylene Market Dynamics

Driver

Rising Demand for Sustainability and Eco-Friendly Solutions

The increasing focus on reducing environmental impact and strict regulations is driving the adoption of circular economy principles, pushing towards bio-based polyethylene and low-toxicity chemicals. Forcing manufacturers to invest in R&D to ensure sustainable products with safety and environmental standards

Market Restraining Factor

Availability of alternatives, including Polypropylene and Polyethylene Terephthalate Products, to limit Polyethylene adoption

Polyethylene shows chemical resistance, flexibility, moldability, and low cost, boosting the demand. But the PP and PET offer superior clarity, rigidity, and heat resistance, align with the circular economy strategy, its focus on the reduction of carbon footprint. Therefore, these alternatives represent a key restraining factor for the global polyethylene market.

Market Opportunities

Are there Significant Opportunities related to Environmental Concerns and Sustainability?

The growing environmental concern and emphasis on sustainable practices are major opportunities that include bio-based polyethylene and advanced recycling. The rising focus on sustainable alternative driving market towards polyethylene derived from renewable resources. The growing investment and innovation in chemical and mechanical recycling technologies can convert plastic waste into high-quality raw feedstock for the application sector.

Which Specific Product Types offer the Most Growth Potential?

The demand for high-performance and specialized grades shows an emerging opportunity in high-density polyethylene and Ultra-high molecular-weight polyethylene due to its strength, durability accelerating demand in packaging, industrial components, medical implants, and protective gear offers market expansion.

How is Artificial Intelligence (AI) Transforming PE Manufacturing?

The integration of AI and automation in manufacturing processes can optimize supply chains and enhance product efficiency through smart manufacturing. The predictive analytics increase operational efficiency by lowering global production costs. The AI-powered system focuses on quality control and the development of advanced material design needed in automotive, healthcare, and telecommunication.

Additionally, AI fosters innovation and development of new polymerization techniques and advanced catalysts to create polyethylene with improved strength for films in medical devices.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5545

Polyethylene Market Segmentation Insights

Product Type Insights

How High-Density Polyethylene Segment Dominate the Polyethylene Market in 2025?

The high-density polyethylene dominated the market in 2025, driven by massive demand for rigid & flexible packaging and a superior strength-to-density ratio with versatile performance in various industrial, commercial, and technology-driven applications. HDPE corrosion resistance to chemicals and moisture aligns with its durability, driving its adoption in underground water supply, sewage, and gas distribution systems, and for preservation of product integrity in food & beverages.

Additionally, market leadership is boosted by its high recyclability, which supports sustainability targets and technological advancements like bimodal manufacturing and AI-driven process optimization. This segment plays a crucial role in infrastructure, construction projects, and specialized industries.

The low-density polyethylene (LDPE) segment is expected to experience significant growth during the forecast period, driven by its flexibility, high toughness, moisture resistance, and cost-effectiveness, making it the preferred choice in flexible packaging, lightweight & high-performance material in automotive and agricultural films for greenhouses. The growing focus on the circular economy principle, coupled with ongoing innovation in bio-based and advanced recycled LDPE accelerating the market expansion.

Application Insights

Which Application Segment Leads the Polyethylene Market?

The bottles and containers segment led the market with the largest share in 2025. The growth is driven by inherent material properties of polyethylene, which provide an exceptional moisture barrier and robust chemical resistance necessary for preserving the safety and efficiency of products across food, beverage, and pharmaceutical applications. The advanced techniques, like advanced blow molding, which allow for lightweight yet durable container designs with enhanced manufacturing efficiency and performance, are boosting this segment.

The films and sheets segment is projected to grow at the fastest CAGR due to its material's adaptability in agricultural plasticulture and its key role in flexible packaging for the booming e-commerce and logistics sectors. The segment future held by the mono-material revolution, replacing non-recyclable laminates with fully recyclable single-layer systems to meet circular economy goals. Additionally, the development of bio-based films supports a sustainable solution that drives market expansion.

End Use Insights

How did the Packaging Segment hold the Largest Share of the Polyethylene Market?

The packaging segment dominated the market in 2025. The leadership is driven by the expansion of e-commerce and the adoption of high-performance bio-based resins, leading this segment. The growing emphasis on the circular economy plays a vital role in the dominance of polyethene in flexible and rigid packaging, including plastic bags, pouches, and bottles, ensuring product safety, freshness, and extended shelf life.

The construction segment is projected to grow at the fastest CAGR during the projected period, driven by energy-efficient construction practices and sustainable infrastructure fueled by increasing adoption of high-performance piping, vapor barriers, geomembranes, and insulation materials that offer durability, corrosion resistance, and flexibility, making it critical for water distribution, drainage, and energy-efficient buildings.

Regional Insights

How did Asia Pacific Dominate the Polyethylene Market?

The Asia Pacific polyethylene market volume was estimated at 53.11 million tons in 2025 and is projected to reach USD 78.99 million tons by 2035, growing at a CAGR of 3.71% from 2026 to 2035.

Asia Pacific dominated the market, driven by massive manufacturing infrastructure and rapid urbanization. The growing emphasis on sustainability and high-tech manufacturing to meet environmental regulations is accelerating the market. The rising investment in advanced petrochemical capacity and the development of chemical recycling infrastructure ensure its position as the primary consumer and producer of high-performance resins. The leadership is continued by a robust production ecosystem combined with digital supply chains that support the packaging, automotive, and construction sectors.

China Polyethylene Market Growth Trends

China's leadership is driven by the rapid adoption of circular economy initiatives, decarbonization goals, and enhanced self-sufficiency in advanced polymer production. This region focuses on large-scale chemical recycling, integration of bio-based feedstock, and industrial modernization in the electric vehicle and telecommunications sectors.

Why is North America the Fastest-Growing Region in the Polyethylene Industry?

North America is emerging as the fastest-growing region in the market during the forecast period, driven by the vast deployment of advanced chemical recycling infrastructure, rapid transition towards high-tech sustainable material solutions, and the industry-wide adoption of bio-based resins to meet stringent decarbonization goals. This region is a global leader in abundant raw material supply, circular economy innovation, and high demand for sophisticated packaging that offers superior durability and lower environmental impact.

U.S. Polyethylene Market Trends

The U.S. market is driven by innovation in recycling and technological advancement in manufacturing to optimize production efficiency. The rising demand in the packaging, construction, and automotive sectors is emerging as a fast-growing region for polyethylene use. The focus on sustainability is also driving the region's expansion.

Europe Polyethylene Market Trends

The polyethylene market in Europe is projected to experience steady growth throughout the forecast period. One of the key drivers supporting this expansion is the strong focus of regional governments on strengthening the healthcare sector. Polyethylene is widely used in medical packaging, tubing, and other healthcare applications, which aligns well with Europe’s emphasis on innovation, safety, and high-quality medical services.

Germany holds a prominent share of the European polyethylene market and is expected to grow at a CAGR of 4.9% during the forecast period. The country’s strong manufacturing base plays a major role in driving polyethylene demand. Extensive usage of polyethylene in the automotive sector and industrial manufacturing further supports market growth in Germany.

Italy’s polyethylene market is also expected to see notable growth in the coming years. Italy’s strong cultural focus on fashion and design significantly influences demand from the textiles and apparel industry. Due to its versatility, polyethylene is increasingly used in creative and functional design applications, supporting the production of stylish and innovative clothing.

Central & South America Polyethylene Market Trends

The polyethylene market in Central and South America is expected to grow steadily over the forecast period. Rapid expansion of e-commerce and evolving consumer preferences are boosting demand for polyethylene, particularly in packaging applications.

Brazil is expected to record a CAGR of 4.8% during the forecast period. The material’s affordability and flexibility make polyethylene a popular choice for packaging across multiple industries. Its ability to meet diverse packaging requirements continues to drive consistent growth in the Brazilian market.

Middle East & Africa Polyethylene Market Trends

The polyethylene market in the Middle East and Africa is projected to grow significantly over the forecast period. The region’s abundant availability of petrochemical feedstocks such as ethane and propane makes it a major global production hub for polyethylene. Proximity to extensive hydrocarbon reserves enables cost-efficient manufacturing and strengthens export potential.

In the UAE, the polyethylene market is expected to grow at a CAGR of 4.9% during the forecast period. Rising demand from the logistics and transportation sectors is a key factor supporting market expansion, as polyethylene is widely used in packaging and material handling solutions.

More Insights in Towards Chemical and Materials:

- Polyethylene Furanoate (PEF) Market Size to Hit USD 3,233.78 Mn by 2035

- Polyethylene Terephthalate Catalyst Market Size to Hit USD 1,321.75 Mn by 2034

- U.S. Recycled Polyethylene Terephthalate Market Size to Reach USD 7.53 Bn by 2034

- Linear Low-Density Polyethylene (LLDPE) Market Size to Reach USD 118.69 Bn by 2034

- Polyethylene Terephthalate (PET) Market Size to Reach USD 68 Bn by 2034

- Polyethylene Glycol (PEG) Market Volume to Exceed 788,565.1 Tons by 2034

- Polyethylene Wax Market Size to Reach USD 3.56 Bn By 2034v

- Mechanical & Chemical Recycling of Polyethylene Market Size, Share | CAGR of 10.29%

- Low-Density Polyethylene (LDPE) Market Size to Reach USD 80.34 Billion by 2034

- Polyethylene Market Size to Surpass USD 268.36 Billion 2035

- Organosilicon Polymers Market Size to Hit USD 29.88 Bn by 2035

- Polymeric Methylene Diphenyl Diisocyanate Market Size to Hit USD 28.49 Bn by 2035

- Polymer Nanocomposites Market Size to Hit USD 60.89 Bn by 2035

- Conductive Polymers Market Size to Surpass USD 14.81 Bn by 2035

- Polybutene-1 Market Size to Hit USD 1,061.10 Million by 2035

- Unsaturated Polyester Resin Market Size to Hit USD 33.40 Bn by 2035

- Polyester Fiber Market Size to Hit USD 274.58 Billion by 2035

- U.S. Recycled Polyolefins Market Size to Surpass USD 21.68 Bn by 2035

- Polyphenylene Sulfide Market Size to Hit USD 4.89 Billion by 2035

- Ion-Conductive Polymers Market Size to Hit USD 8.75 Bn by 2035

- Europe Biopolymers Market Size to Surge USD 18.23 Billion by 2035

- U.S. Biopolymers Market Size to Worth Around USD 22.16 Bn by 2035

- Thermoplastic Polyimides Market Size to Hit USD 1,926.61 Mn by 2035

- Polyphthalamide Market Size to Reach USD 7.82 Bn by 2035

- Stainless Steel-Filled Polymer Filaments Market Size to Hit USD 157.82 Mn by 2035

- Polyaniline Market Size to Surpass USD 3.22 Billion by 2035

- Polyglycerol Market Size to Hit USD 22.30 Billion by 2035

- Polyurethane Market Size to Worth USD 152.38 Billion by 2035

- Europe Bioplastics and Biopolymers Market Size to Reach USD 34.37 Bn by 2035

- U.S. Bioplastics and Biopolymers Market Size to Surpass USD 34.37 Bn by 2035

- Asia Pacific Biopolymers Market Size to Worth USD 26.39 Bn by 2035

- Polylactic Acid Market Size to Reach USD 11.74 Bn by 2035

- Smart Textile Polymers Market Size to Hit USD 9.63 Million by 2035

- Biopolymer Coatings Market Size to Reach USD 109.08 Bn by 2035

- Europe Specialty Polymers Market Size to Surpass USD 72.19 Bn by 2035

- Polymer Coated Fabrics Market Size to Hit USD 40.13 Bn by 2035

- Asia Pacific Specialty Polymers Market Size to Surpass USD 70.70 Bn by 2034

- U.S. Recycled Polyester Market Size to Surpass USD 7.16 Bn by 2034

- U.S. Biopolypropylene Market Size to Hit USD 698.38 Mn by 2034

- U.S. Specialty Polymers Market Size to Surpass USD 59.52 Bn by 2034

- Polyethylene Terephthalate Catalyst Market Size to Hit USD 1,321.75 Mn by 2034

- Bio-Based Polypropylene Market Size to Hit USD 6,977.54 Mn by 2034

- Green Polypropylene Market Size to Hit USD 72.70 Billion by 2034

- Renewable Polypropylene Market Size to Surge USD 133.67 Billion by 2034

- Europe Polymer Market Size to Hit USD 642.73 Billion by 2034

- Polymer Foam Market Size to Surge USD 273.58 billion by 2034

- Polypropylene Compounds Market Size to Surge USD 50.86 Billion by 2034

- Biopolymers Market Size to Reach USD 53.68 Billion by 2034

- Liquid Crystal Polymers Market Size to Hit USD 6.73 Billion by 2034

- U.S. Recycled Polyethylene Terephthalate Market Size to Reach USD 7.53 Bn by 2034

- U.S. Polymer Foam Market Size, Share, Trends & Growth Report, 2034

- Polyvinylpyrrolidone (PVP) Market Size to Surge USD 6.07 Bn by 2034

- Polyolefin Compounds Market Size to Reach USD 42.84 Billion by 2034

- Polyester Hot Melt Adhesives (PHMAs) Market Size to Hit USD 1,491.92 Million by 2034

- Polymer Chameleon Market Size to Reach USD 1,225.52 Mn by 2034

- Extruded Polystyrene Market Size to Hit USD 7.61 Billion by 2034

Top Companies in the Polyethylene Market & Their Offerings:

Tier 1:

- Dow: High-performance LLDPE and enhanced resins like DOWLEX™ and ELITE™ for flexible packaging and infrastructure.

- BASF SE: Specialized polyethylene glycols (PEGs) and resins used in pharmaceutical, automotive, and industrial chemical processing.

- Exxon Mobil Corporation: Performance polymers like Exceed™ S and Enable™ are engineered for extreme toughness in packaging and agricultural films.

- Borealis AG: Value-added PE produced via Borstar® technology, focusing on recyclability and advanced energy infrastructure applications.

- Braskem: Market leader in sustainable PE, specifically its "I'm green™" bio-based polyethylene made from renewable sugarcane.

- Formosa Plastics: Mass-scale production of Formolene® HDPE, LDPE, and LLDPE for consumer containers and film extrusion.

-

INEOS Group: Specialized Eltex® grades for high-durability applications like pressure pipes, fuel tanks, and recycled polymer blends.

Recent Developments

- In October 2025, Mitsui Chemicals and Polyplastics announced a strategic partnership aimed at enhancing the Polyplastics customer network and marketing operation to meet the growing demand for high-performance engineering plastic in the electrical and automotive sectors.

Polyethylene Market Top Key Companies:

- BASF SE

- Borealis AG

- Braskem

- Dow

- Exxon Mobil Corporation

- Formosa Plastics

- INEOS Group

- LG Chem

- LyondellBasell Industries Holdings B.V.

- Mitsubishi Chemical Corporation

- MOL Group

- SABIC

- China Petrochemical Corporation (Sinopec)

Polyethylene Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Polyethylene Market

By Product Type

- Low-density Polyethylene (LDPE)

- High-density Polyethylene (HDPE)

- Linear Low-density Polyethylene (LLDPE)

By End Use

- Packaging

- Construction

- Automotive

- Agriculture

- Consumer Electronics

- Other End-uses

By Application

- Bottles & Containers

- Films & Sheets

- Bags & Sacks

- Pipes & Fittings

- Other applications

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5545

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.